The XNX Gas Detector Calibration process ensures accurate gas detection, crucial for workplace safety and regulatory compliance․ It involves specific procedures for zero and span calibration, detailed in the 2022 PDF guide, to maintain precise sensor performance and reliable monitoring of hazardous gases․

1․1 Overview of XNX Universal Transmitter

The XNX Universal Transmitter is a versatile platform supporting various gas detection technologies, including electrochemical, infrared, and catalytic bead sensors․ Designed for flexibility, it accommodates multiple gas types and detection ranges, making it suitable for diverse industrial applications․ Its modular design allows easy integration with existing systems, while features like HART communication enable advanced configuration and monitoring․ The transmitter’s durability and reliability ensure accurate gas detection, supported by detailed calibration procedures outlined in the 2022 PDF guide․

1․2 Importance of Regular Calibration

Regular calibration of the XNX gas detector is essential to ensure accurate and reliable gas detection․ Calibration verifies sensor responsiveness to known gas concentrations, preventing false alarms and ensuring safety․ Over time, sensor accuracy may drift due to environmental factors, aging, or contamination, potentially leading to undetected hazards․ Proper calibration maintains compliance with safety standards and guarantees the detector’s ability to protect people and assets effectively, as outlined in the 2022 PDF guide․

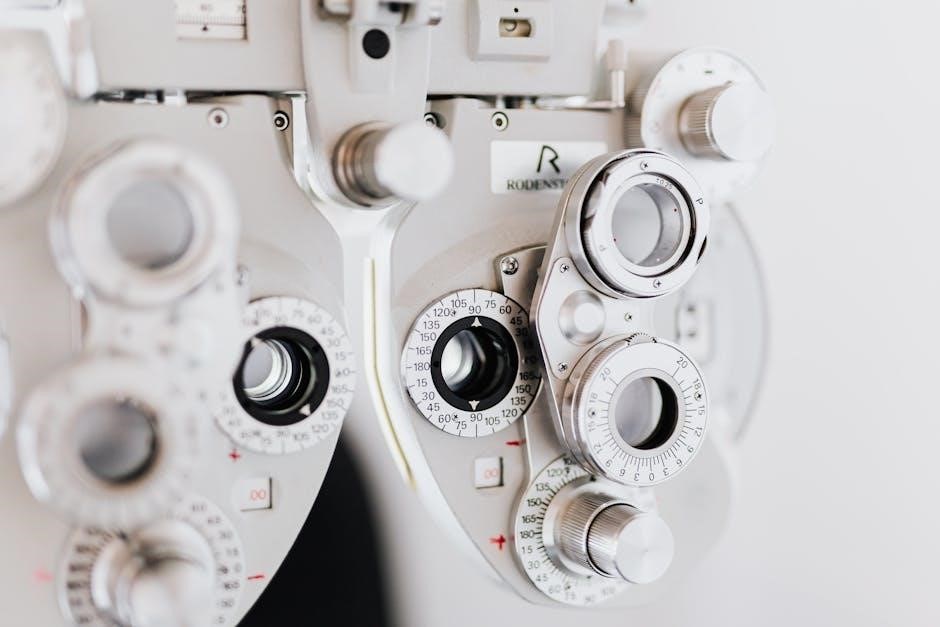

Understanding the Components of XNX Gas Detectors

The XNX gas detector consists of a universal transmitter, sensors (electrochemical, infrared, or catalytic bead), and a calibration cup with gas flow housing, ensuring accurate gas detection․

2․1 Sensors and Their Types (Electrochemical, Infrared, Catalytic Bead)

The XNX gas detectors utilize three primary sensor types: electrochemical, infrared, and catalytic bead․ Electrochemical sensors measure gas concentration through chemical reactions, offering high sensitivity․ Infrared sensors detect gases via absorption of specific wavelengths, ideal for hydrocarbons․ Catalytic bead sensors combust flammable gases, providing reliable LEL detection․ Each type is optimized for specific gas detection needs, ensuring accurate and reliable monitoring in various industrial environments;

2․2 Calibration Cup and Gas Flow Housing

The calibration cup and gas flow housing are essential for accurate gas detector calibration․ The calibration cup fits onto the sensor to apply test gas, ensuring precise exposure․ The gas flow housing directs gas to the sensor, maintaining consistent flow rates․ Proper alignment and sealing are crucial for accurate readings․ These components are designed to simplify the calibration process, ensuring reliable sensor performance and compliance with safety standards in industrial gas detection systems․

Calibration Process for XNX Gas Detectors

The calibration process ensures accurate gas detection by adjusting the sensor’s response to known gas concentrations, critical for reliable monitoring and workplace safety․

3․1 Zero Gas Calibration Procedure

The zero gas calibration procedure involves exposing the sensor to zero air to establish a baseline reading․ This step ensures the detector accurately measures gas concentrations by setting the sensor’s reference point․ Begin by attaching the calibration cup to the sensor and applying zero gas․ Access the calibration menu and select the zero gas option․ The system will automatically adjust the sensor’s baseline․ Once complete, the display will confirm the procedure’s success; This process is essential for maintaining accurate and reliable gas detection․ Always follow the manufacturer’s guidelines for optimal results․

3․2 Span Gas Calibration Procedure

Span gas calibration adjusts the sensor’s response to a known gas concentration, ensuring accurate upper range measurements․ Attach the calibration cup and select the appropriate gas type in the menu․ Apply the span gas, and the system will automatically adjust the sensor’s sensitivity․ This step is crucial for ensuring precise detection of target gas levels․ The procedure confirms the sensor’s ability to measure accurately across its range, maintaining reliability and safety in gas monitoring applications․

3․3 Steps for Successful Calibration

Successful calibration involves preparing the detector, stabilizing the sensor, and following precise steps․ Attach the calibration cup to the sensor and ensure proper gas flow․ Access the calibration menu, select the gas type, and initiate the process․ Allow the system to automatically adjust sensor settings․ Verify completion through confirmation screens and ensure all readings align with specifications․ Proper execution ensures accurate detection, reliability, and compliance with safety standards, safeguarding personnel and facilities from gas hazards․

Accessing the Calibration Menu

Navigate the XNX Universal Transmitter interface to access the calibration menu․ Select the appropriate options to initiate zero or span calibration, ensuring proper setup for accurate gas detection․

4․1 Navigating the XNX Universal Transmitter Interface

Navigating the XNX Universal Transmitter interface involves accessing the calibration menu through a series of intuitive steps․ Users can select the desired calibration mode by using the menu-driven system․ The interface provides clear options for zero and span calibration, allowing users to follow on-screen instructions․ Ensure the sensor is stabilized before proceeding․ Use the navigation keys to scroll through options and confirm selections․ The interface guides users through the process, ensuring accurate and efficient calibration setup․

4․2 Using the Gas Calibration Menu

Access the Gas Calibration Menu via the XNX Universal Transmitter interface․ Select the desired calibration type, such as zero or span, and follow the on-screen instructions․ Apply calibration gas as prompted, ensuring the sensor is stabilized․ Confirm gas type and concentration to proceed․ The system will display real-time data and confirm calibration success․ If issues arise, refer to troubleshooting options within the menu․ Proper use ensures accurate sensor response and reliable gas detection, maintaining workplace safety and compliance with regulations․ Always follow manufacturer guidelines for optimal results․

Preparation for Calibration

Ensure sensor stabilization for 30 minutes before starting․ Select the correct calibration gas and confirm its concentration․ Clear the area of residual gases to prevent interference․

5․1 Ensuring Sensor Stabilization

Sensor stabilization is critical for accurate calibration․ Allow the sensor to stabilize for at least 30 minutes after power-up․ Environmental factors like temperature and humidity must be constant during this period․ Ensure no residual gases are present near the sensor, as they can interfere with stabilization․ Proper stabilization ensures the sensor responds accurately to calibration gases, forming the foundation for reliable gas detection performance․ Skipping this step may lead to calibration errors and unsafe readings․ Always follow the manufacturer’s guidelines for stabilization times․

5․2 Selecting the Correct Calibration Gas

Selecting the correct calibration gas is essential for accurate sensor response․ Refer to the XNX Technical Manual for specific gas type and concentration requirements․ Ensure the calibration gas matches the sensor’s target gas and detection range․ Using incorrect gas can lead to inaccurate readings or safety hazards․ Always verify the gas concentration and expiration date before use․ This step ensures the detector operates within specified limits, providing reliable gas detection and compliance with safety standards․

Troubleshooting Calibration Issues

Troubleshooting calibration issues involves identifying common causes like sensor inaccuracy or gas flow problems․ Refer to the 2022 PDF guide for detailed diagnostic steps and solutions to ensure accurate detector performance and compliance with safety standards․

6․1 Common Causes of Calibration Failure

Calibration failure in XNX gas detectors often stems from sensor contamination, incorrect gas flow, or unstable environmental conditions․ Improper use of calibration gas, such as incorrect concentration or type, can also disrupt accuracy․ Additionally, sensor aging, exposure to interfering gases, or mechanical issues with the calibration cup may cause errors․ Ensuring proper stabilization time and verifying gas cylinder integrity are critical to avoiding these common pitfalls, as outlined in the 2022 PDF guide for XNX gas detector calibration․

6․2 Resolving Sensor Inaccuracy

Resolving sensor inaccuracy involves cleaning or replacing the sensor if contaminated․ Ensure proper gas flow and stabilize the sensor for 30 minutes before recalibration․ Verify environmental conditions, such as temperature and humidity, are within acceptable ranges․ If issues persist, replace the sensor with a new one of the same type․ Regular maintenance and adherence to the 2022 PDF guide’s procedures help restore accuracy and ensure reliable gas detection performance․

Post-Calibration Documentation

Post-calibration documentation involves recording calibration dates, results, and adjustments․ Maintain detailed records for compliance, auditing, and future reference, ensuring adherence to safety standards and regulatory requirements;

7․1 Maintaining Calibration Records

Maintaining accurate calibration records is essential for compliance and auditing․ Records should include calibration dates, results, and adjustments made․ Detailed documentation ensures traceability and verifies adherence to safety standards․ Regular updates and secure storage of records prevent data loss․ Referencing the 2022 PDF guide and XNX Technical Manual provides best practices for organizing and retaining calibration data effectively․

7․2 Compliance and Reporting Requirements

Compliance with industry standards and regulations is critical for workplace safety․ Regular calibration ensures adherence to OSHA and ISA guidelines․ Detailed reports must be generated, including calibration certificates and sensor performance logs․ These documents must be submitted to relevant authorities and maintained for audit purposes․ Failure to comply can result in legal penalties and operational shutdowns․ The 2022 PDF guide outlines specific reporting formats and submission timelines to ensure full regulatory adherence․

Maintenance and Service Intervals

Regular maintenance ensures optimal XNX detector performance․ Follow the manufacturer’s schedule to prevent sensor degradation and ensure accurate gas detection; Schedule includes quarterly checks and annual servicing for reliability․

8․1 Recommended Maintenance Schedule

Adhere to a structured maintenance plan to ensure the XNX gas detector operates efficiently․ Perform daily checks of sensor integrity and gas flow․ Weekly, inspect the calibration cup and housing for blockages․ Monthly, clean or replace filters and test sensor response․ Every six months, verify transmitter settings and recalibrate if necessary․ Annually, conduct a full system inspection and replace aging components․ Always follow the Honeywell XNX Technical Manual for detailed procedures to maintain accuracy and compliance with safety standards․

8․2 When to Replace Sensors or Components

Sensors and components in the XNX gas detector should be replaced when performance falls below specified thresholds or when calibration becomes inconsistent․ Replace sensors every 2-5 years, depending on exposure to contaminants and environmental factors․ If a sensor fails calibration or shows significant drift, immediate replacement is necessary․ Additionally, replace any physically damaged components to maintain reliability․ Always consult the Honeywell XNX Technical Manual for specific guidelines on replacement intervals and procedures to ensure optimal detector performance and safety․

Proper XNX gas detector calibration ensures accurate gas detection, essential for workplace safety and compliance․ Regular calibration, as outlined in the 2022 PDF guide, guarantees reliable performance and adherence to safety standards․

9․1 Summary of Best Practices

Best practices for XNX gas detector calibration include allowing sensors to stabilize for 30 minutes before calibration, using the correct calibration gas, and following the 2022 PDF guide․ Regular zero and span calibration ensures accuracy and reliability․ Always refer to the Honeywell XNX Technical Manual for specific procedures․ Maintain detailed calibration records for compliance and traceability․ Schedule routine maintenance to replace sensors or components as needed to ensure ongoing performance and safety in gas detection applications․

9․2 Ensuring Ongoing Accuracy and Safety

Regular maintenance and adherence to calibration schedules are critical for ensuring ongoing accuracy and safety․ Sensors should be checked for stability before calibration, and the correct calibration gas must be used to maintain precision․ Referencing the 2022 PDF guide ensures compliance with updated procedures․ Documenting calibration results and performing routine checks helps identify potential issues early․ Always follow the Honeywell XNX Technical Manual for detailed instructions to maintain reliable gas detection and ensure a safe working environment․

References and Resources

Refer to the Honeywell XNX Technical Manual for detailed calibration procedures․ Additional resources include the Quick Start Manual, Safety Manual, and downloadable PDF guides for comprehensive support․

10․1 Honeywell XNX Technical Manual

The Honeywell XNX Technical Manual provides comprehensive details on gas detector calibration, maintenance, and troubleshooting․ It outlines step-by-step procedures for zero and span calibration, sensor stabilization, and fault resolution․ The manual also includes safety guidelines, wiring diagrams, and compliance requirements, ensuring users can maintain optimal performance and reliability․ Refer to this resource for detailed technical specifications and best practices for XNX gas detectors․

10․2 Additional Support Materials

Additional support materials, such as user guides, quick start manuals, and safety manuals, complement the Honeywell XNX Technical Manual․ These resources provide detailed instructions for calibration, maintenance, and troubleshooting․ They include wiring diagrams, compliance guidelines, and troubleshooting tips, ensuring users can optimize their XNX gas detectors․ Available in PDF formats, these materials offer accessible and comprehensive support for maintaining accurate and reliable gas detection systems, aligning with regulatory standards and safety protocols․